Assembling components and bikes

The assembly of components and bikes at Bike Fun International is synonymous with precision and quality. Through the use of sophisticated processes and meticulous quality control, we ensure that every bike produced meets the highest standards.

Before final assembly on the production line, it is essential to prepare semi-finished products, including not only wheels but also forks, handlebars, carriers, mudguards and more. In addition, cables are threaded and chains adjusted.

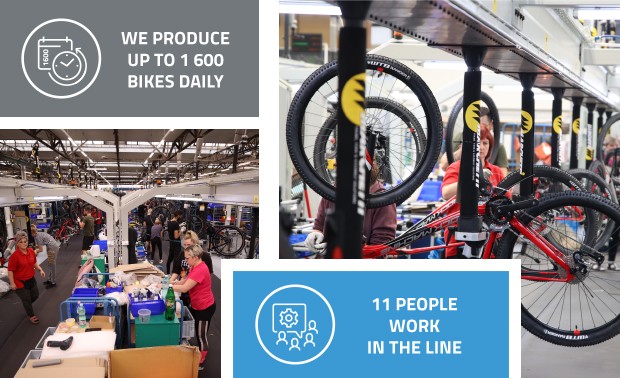

We assemble bikes on air lines, which is an innovative approach to assembly. Unlike traditional strap systems, the bike is suspended from above, behind the seat tube, making it much easier to manipulate. This suspension system not only improves ergonomics, but also allows the bike to be safely rotated to any angle without risk of damage. This modern technology helps us to achieve higher efficiency and quality in bicycle production.

We currently have 10 air lines, each with its own team of workers.

Quality is a key element of our production. After assembly, we carry out random checks on finished bikes and every electric bike undergoes a thorough final inspection.

After a successful inspection, the bicycles are packed in boxes or covers typical of bicycles produced for the Dutch market. Each bike is then weighed. If the weight of the bike matches the weight specified in our system, a label is automatically printed and the bike is ready for transport to the finished goods warehouse.

If the weight is out of tolerance, the system does not print the label and a warning message is displayed: "WEIGHT OUT OF TOLERANCE". The bike is then unpacked and inspected to ensure that all components are in order. Any defects found are then rectified to ensure that every bike that leaves our factory meets the highest quality standards.

The production of high-end bicycle models is carried out in a specialized area where bikes are manually assembled on a so-called "carousel" by the most experienced workers.

We focus on achieving high quality in all production phases and processes:

We achieve this through the modern SyteLine information system, which enables comprehensive material planning and efficient production management.

Quality control is emphasised from the outset, starting with the incoming inspection of purchased components, where we implement progressive internal processes.

Dealing with complaints is crucial to us and that's why we use 8D reports to ensure maximum customer satisfaction.

Improving the working environment is important to us and we adhere to the 5S principles, which include maintaining a well-organised workspace and long-term sustainability of order.

We also apply the Kaizen principle, which focuses on continuous small improvements in individual production processes and working conditions, leading to increased work efficiency and overall process refinement.